The Specialty Equipment Market Association (SEMA) show brings some of the world’s best fabricators and manufacturers to Las Vegas each year. Among the sea of tidy, high-quality builds lurk projects that must have been conceived on a napkin with a crayon. The Facebook group, “SEMA Fails,” documents these project disasters, pointing out parts that are superfluous, or just plain unsafe.

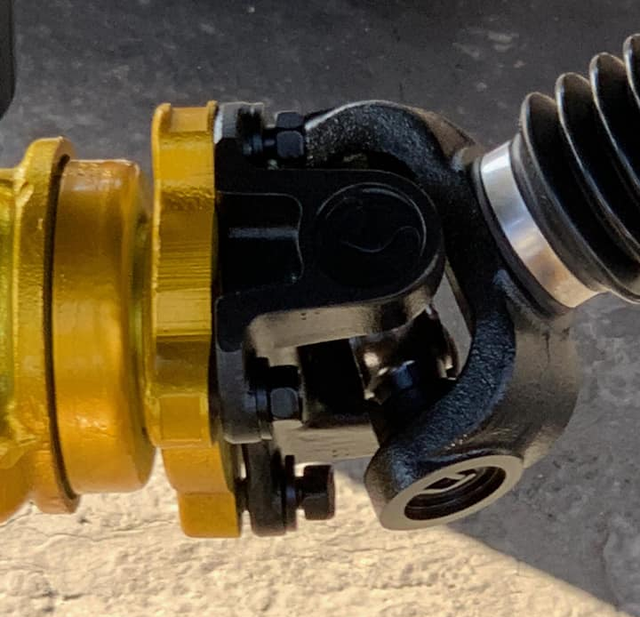

The most common issue at SEMA seems to be ill-fitted universal joint straps. The straps shown in a few of these pictures appear to be too small for the application, but the builders apparently decided to use them anyway. This shoddy u-joint strap may allow the truck to roll onto the show floor, but wouldn’t last long at on the road, where the strap cracking or bolts shearing off is likely, and thus very dangerous.

Another common sight are bolts that aren’t tight. In a few of the pictures, we see driveshaft yokes and differential flanges with bolts inserted, but not actually tightened. This is puzzling. Taking a few minutes to tighten components that could violently fail is a good idea. But maybe the builder’s schedule was really tight. Or they forgot to buy the right size of bolt?

Displaying a project at SEMA requires tons of customization, so it’s rare to see a vehicle without aftermarket wheels. In the case of the pictured wheel, it appears the builder didn’t account for a proper bore size, which caused the wheel to overlap with the internal studs. Instead of finding a wheel with the correct bore size or machining these wheels so they’d fit over those studs, this shop decided to install the wheels without seating them to the hub. Since the wheels are seated against the top of the studs and not the actual hub, driving this truck would result in some vibration. At some point, the studs would break, and the wheels would fall off.

Driveshafts are a common failure point on extremely lifted trucks. Its problem many of the brodozers on display simply avoided; some trucks at SEMA are lifted so high, they can’t actually fit a driveshaft, and the creations are pushed onto the show floor. The phenomenon is called “Bluetooth driveshafts” by many in the industry. In the photo below, the builder noticed that the driveshaft was too long, so they decided just to bend the shaft to fit and cover it with a boot. While the truck appears capable at a standstill, the imbalanced driveshaft would shake itself apart if driven.

Our final photo shows another lifted truck, this one slathered in red paint underneath. At first glance it doesn’t look terrible, but notice the truss on top of the rear axle. It’s not properly attached.

In most cases, when attaching a truss to the top of an axle, you should weld the pair together. This allows the truss to distribute load across the axle tubes evenly. In this case, it seems the builder sent this axle housing to be powder coated before figuring out that they wanted to weld on a truss. Instead, the truss is attached with u-bolts. It may look purposeful, but this fix is regressive, because it puts load on four points instead of distributing it evenly across the truss. There are some trusses that can bolt onto an axle housing, but those are usually of a different design, which most often bolts on from the bottom of the housing.

These are just a few of the fails that SEMA-goers have spotted, but we’re sure there are plenty more to be uncovered. If TV-show conventions are to be believed, many car builders don’t actually start on their project until about a week before they’re supposed to head to the big show. Guess everything on TV isn’t smoke and mirrors.